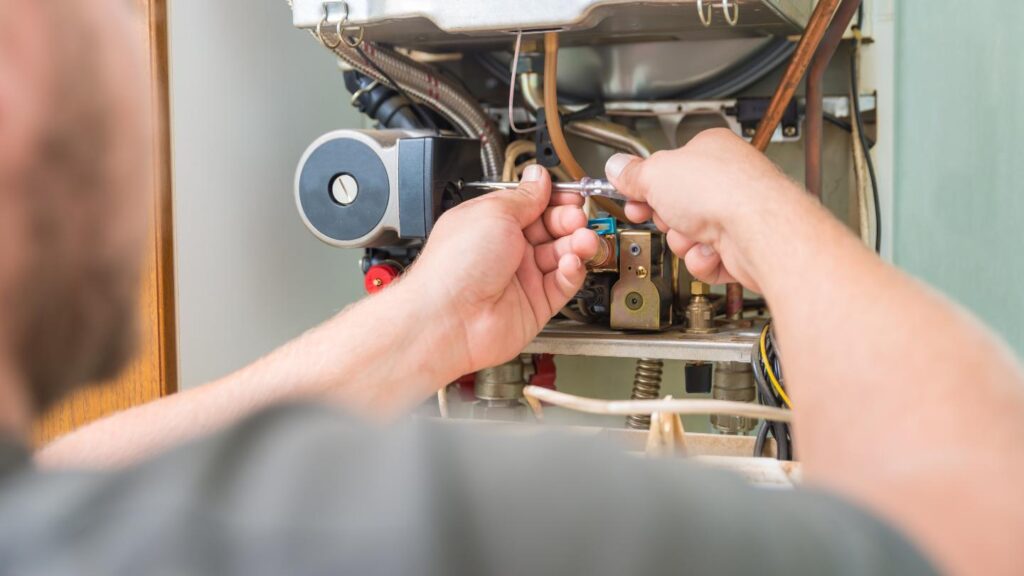

What Are The Warning Signs of a Faulty Furnace Ignitor?

Is your furnace struggling to keep your home warm? Identifying the warning signs of a faulty furnace ignitor is vital for maintaining a comfortable living environment. This blog outlines the most common signs of ignitor issues and explains how professionals address them to ensure your furnace operates efficiently and reliably.

Key Takeaways

- Furnace ignitors are critical components that initiate heat generation. Understanding their function is essential for identifying potential problems early.

- Common signs of a faulty ignitor include failure to ignite, blowing cold air instead of warm, frequent cycling on and off, unusual noises from the furnace, and repeated circuit breaker tripping.

- Regular professional maintenance and inspections are key to preventing ignitor issues and addressing them before they lead to larger problems.

Understanding the Role of a Furnace Ignitor

A furnace ignitor plays a crucial role in initiating the combustion process by lighting the gas, enabling the furnace to generate heat and maintain a comfortable indoor environment. If this component fails, your furnace will not produce the warmth needed to keep your home cozy. Modern furnaces commonly use either electric hot surface ignitors or intermittent pilot systems, both designed for enhanced reliability and performance.

Electric hot surface ignitors operate when they receive an electrical signal, heating a durable filament until it glows red-hot. This heat ignites the gas mixture, initiating the heating process. The proper functioning of these ignitors is vital—any malfunction can prevent the furnace from igniting, disrupting your heating system during colder months.

Professionals thoroughly inspect furnace ignitors during routine maintenance to detect potential issues like wear, damage, or inefficiencies. By understanding how these components function and relying on expert care, homeowners can avoid significant disruptions and maintain efficient heating throughout the season.

Common Indicators of a Faulty Furnace Ignitor

The deterioration of a furnace ignitor typically presents several noticeable signs. Recognizing these warning indicators early can help prevent further damage and costly repairs. Here are the most common symptoms of a faulty ignitor:

- Failure of the furnace to ignite.

- Blowing cold air instead of hot air.

- Frequent cycling on and off.

- Unusual noises coming from the unit.

- Repeated tripping of the circuit breaker.

Identifying these signs promptly allows professionals to diagnose and address the issue effectively, safeguarding the efficiency and longevity of your heating system. Below, we explore these symptoms in detail and explain how experts handle them to restore functionality.

Furnace Won’t Ignite

A furnace that fails to ignite is often a key indicator of a malfunctioning ignitor. Even if the thermostat is correctly set, a defective ignitor will prevent the furnace from initiating the heating process. Clicking sounds without activation also strongly suggests ignitor issues.

Rather than attempting to inspect components like the ignitor or flame sensors yourself, professionals use specialized tools to determine the cause of ignition failure. Cleaning or replacing flame sensors and ignitors are tasks best left to trained technicians to ensure proper handling and prevent further damage.

Read more: What Does a Furnace Flame Sensor Do?

Furnace Blows Cold Air

If your furnace is blowing cold air despite being set to heat, this could indicate that the ignitor is not successfully lighting the gas. Without sufficient heat from the ignitor, the furnace cannot warm the air.

Professionals address this issue by conducting a thorough system evaluation to determine whether the problem lies with the ignitor, the gas supply, or another component. They then make the necessary repairs or replacements to restore the furnace’s ability to heat your home efficiently.

Frequent Cycling On and Off

Frequent cycling occurs when the ignitor struggles to maintain its charge, causing the furnace to turn on and off repeatedly. This reduces heating efficiency and may signal underlying problems requiring professional intervention.

Trained technicians identify the root cause of cycling and perform targeted repairs to stabilize the system, ensuring consistent performance.

Strange Noises from the Furnace

Unusual noises like banging or rumbling often point to ignitor-related issues. Electrical surges or short circuits can cause these sounds and potentially damage the ignitor.

Experts recommend addressing these noises promptly to prevent further complications. A professional inspection can determine whether the issue is ignitor-related or if other furnace components require attention.

Repeated Circuit Breaker Tripping

A frequently tripping circuit breaker could signal electrical problems involving the ignitor. Continuous use in such conditions can compromise your furnace’s safety and performance.

For safety reasons, professionals recommend leaving the breaker off until a trained technician can inspect and resolve the underlying issue. They ensure all electrical components are functioning correctly to prevent recurring tripping.

Causes of a Faulty Furnace Ignitor

Understanding the causes of a faulty furnace ignitor is essential for preventing larger system issues and ensuring your furnace operates reliably. Common factors contributing to ignitor malfunctions include the accumulation of dirt and debris, electrical complications, and natural wear and tear. Addressing these issues proactively can help maintain your furnace’s performance.

Dirt and Debris Accumulation

Over time, dirt and debris can accumulate on the furnace ignitor, impeding its functionality. This buildup can also affect components like flame sensors, disrupting the ignition process. Left unaddressed, these obstructions may cause the ignitor to overheat or fail prematurely.

Routine maintenance performed by HVAC professionals ensures the ignitor and other components are kept clean and in optimal condition. Technicians use specialized tools to remove debris safely, preventing overheating and maintaining system efficiency.

Electrical Problems

Fluctuations in voltage and power surges can significantly impact the performance of a furnace ignitor. These electrical inconsistencies may cause short circuits, leading to frequent circuit breaker trips and ignitor damage.

Trained professionals assess the furnace’s electrical system during inspections to identify and resolve irregularities. By ensuring a stable power supply and addressing electrical issues promptly, technicians protect the ignitor and other sensitive components from damage.

Wear and Tear Over Time

Furnace ignitors are built to withstand high heat but will naturally degrade over time. Cracking, breaking, or reduced efficiency often signals the end of an ignitor’s lifespan. On average, ignitors last about seven years, depending on usage and maintenance.

Regular inspections by skilled HVAC technicians help identify signs of wear early. Professionals can replace aging ignitors as part of a comprehensive maintenance plan, ensuring the continued reliability of your furnace.

How to Test and Diagnose a Bad Furnace Ignitor

Testing and diagnosing a faulty furnace ignitor is a critical step in identifying issues and restoring proper functionality. While specialized tools like multimeters and visual inspections are commonly used, these tasks are best performed by trained HVAC professionals to ensure safety and accuracy. Below is an overview of how experts approach diagnosing ignitor problems.

Visual Inspection

During a professional inspection, technicians carefully examine the ignitor for visible signs of damage, such as cracks, discoloration, or breaks. This process involves safely removing the service panel to access the ignitor, typically located near the gas entry point and connected by electrical wiring.

Unlike DIY attempts, professional visual inspections are thorough and precise. Experts ensure that no other components are disturbed during the examination. If damage is detected, they recommend repairs or replacements based on the ignitor’s condition.

Using a Multimeter

Technicians use a multimeter to test the ignitor’s resistance and confirm whether it is functioning correctly. They disconnect the ignitor from its wiring connections and measure its resistance levels. Ideally, the reading should fall between 50 and 400 ohms. Any values outside this range typically indicate a defective ignitor.

Using a multimeter requires technical expertise and precise calibration to avoid errors or further damage to the ignitor. Professionals not only test the ignitor but also examine related components, such as wiring, the control board, and the gas valve, to rule out additional issues that might affect the system.

When to Call a Professional

While minor furnace issues might seem manageable, certain problems demand immediate attention from trained HVAC professionals. For instance, if your furnace’s ignitor clicks but fails to light the gas, it indicates a serious malfunction requiring expert diagnosis. Similarly, persistent issues like frequent circuit breaker trips or ongoing ignitor difficulties are clear signs that professional assistance is necessary.

Read more: Top 7 Signs Your Furnace Is Going Out and Needs Repair

Sometimes, the issue goes beyond a faulty ignitor and involves other critical components of the furnace system. Delaying repairs can lead to system-wide damage, higher repair costs, or even safety hazards. Acting promptly when you notice ignitor-related symptoms helps ensure that your furnace remains efficient and reliable.

Professionals are equipped to identify and resolve more complex problems safely and effectively. If your furnace breaker trips repeatedly or you suspect electrical dangers, contacting a certified technician ensures the issue is handled correctly, preventing injuries and protecting your system from further harm.

Maintenance Tips to Prevent Ignitor Issues

Maintaining your furnace ignitor through consistent professional care is vital for its efficiency and longevity. Trained HVAC technicians perform routine cleaning and inspections to prevent dust, debris, or wear from compromising the ignitor’s functionality. These professional maintenance services ensure the ignitor remains effective while preventing unexpected failures.

Regular system check-ups also include cleaning the surrounding area of the furnace to avoid contamination from accumulated dust and debris. Technicians thoroughly inspect the ignitor for any signs of deterioration or overheating, addressing issues before they escalate into costly repairs.

Incorporating a professional maintenance plan not only helps extend the life of the ignitor but also improves the furnace’s overall energy efficiency. Properly functioning electric ignitors contribute to energy savings by ensuring consistent ignition without the need for an uninterrupted gas supply. Relying on expert maintenance services ensures your furnace operates seamlessly throughout all seasons.

Summary

Spotting the warning signs of a faulty furnace ignitor is vital to prevent the inconvenience of a cold home and the expense of major repairs. By understanding the role of a furnace ignitor, recognizing failure symptoms, and addressing common causes, homeowners can take proactive measures to ensure their heating systems remain efficient. Consistent professional maintenance and timely repairs are essential to avoid ignitor-related issues.

For those in need of furnace installation in Port Charlotte, FL, Total Comfort Cooling & Heating Inc. provides comprehensive heating and air conditioning services. Our expert HVAC maintenance and repair plans are customized to suit your system’s requirements. Don’t wait for a breakdown—contact us today for dependable furnace solutions.

Frequently Asked Questions

1. How can I tell if my furnace ignitor is really the problem?

If your furnace isn’t heating, produces cold air, or experiences constant cycling, the ignitor may be faulty. A clicking sound without ignition or a non-glowing ignitor are clear signs. If these symptoms persist, a professional inspection is recommended.

2. Can a dirty furnace ignitor cause long-term damage?

Yes, dirt and debris can prevent the ignitor from functioning properly, leading to overheating and eventually failing. Regular cleaning and maintenance can prevent this and ensure the system operates efficiently.

3. How often should I have my furnace ignitor checked?

It’s best to have your furnace inspected annually as part of a routine maintenance plan. Regular checks help catch potential issues early, preventing costly repairs and ensuring your system operates efficiently during colder months.

READY FOR YOUR NEXT HEATING OR COOLING PROJECT?

Contact us to get a quote and see why our customer service is recognized as the best in the industry.